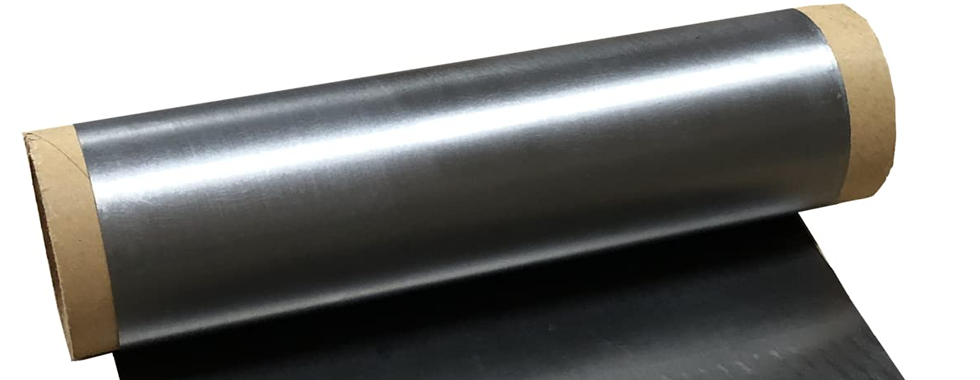

Why Pure Graphite Rolls Are Essential for the Automotive Industry

The automotive industry is constantly evolving, with an increasing emphasis on efficiency, performance, and sustainability. One material that plays a significant role in helping automotive manufacturers meet these demands is pure graphite. In particular, pure graphite rolls have proven to be an indispensable component in various automotive applications due to their unique properties. This blog will explore why pure graphite rolls are essential in the automotive industry and how they contribute to the performance and longevity of vehicle parts.

1. High-Temperature Resistance

One of the most notable properties of graphite is its ability to withstand extreme temperatures without degrading. In the automotive industry, parts such as gaskets, seals, and heat shields often face high temperatures, especially in engines, exhaust systems, and brakes. Pure graphite rolls can maintain their structural integrity even when exposed to high heat, making them ideal for high-performance automotive components. Their heat resistance ensures that critical parts continue to function optimally in extreme conditions.

2. Excellent Lubrication Properties

Graphite is known for its natural lubrication properties. When used in automotive applications, pure graphite rolls help reduce friction between moving parts, such as pistons, bearings, and camshafts. This not only improves the overall performance of the vehicle but also reduces wear and tear, extending the lifespan of critical engine components. In addition, graphite’s lubrication properties can help reduce fuel consumption by improving the efficiency of internal combustion engines.

3. Corrosion Resistance

Automotive components are often exposed to moisture, salt, and various chemicals, all of which can lead to corrosion. Pure graphite rolls are highly resistant to corrosion, ensuring that components such as seals and gaskets maintain their functionality even in harsh environments. This makes graphite rolls an excellent choice for automotive applications where moisture and chemical exposure are a concern, such as in cooling systems and exhaust systems.

4. Sealing and Gasket Applications

Graphite rolls are widely used to create seals and gaskets in automotive engines and exhaust systems. The flexibility and compressibility of graphite allow it to form tight seals that can withstand high pressure and temperature fluctuations. This is crucial for preventing fluid leaks and ensuring that engine components operate efficiently. Pure graphite rolls can be easily cut or customized to the specific dimensions required for different automotive applications, making them versatile and cost-effective solutions for sealing and gasket needs.

5. Electrical Conductivity

Graphite is also a good conductor of electricity, which makes it useful in automotive applications involving electrical components. For example, pure graphite rolls are used in battery applications, particularly in electric vehicles (EVs), where efficient power distribution is crucial. Graphite rolls can help in the creation of conductive paths, ensuring that electrical systems remain reliable and functional under various operational conditions.

6. Lightweight and Durable

In modern automotive design, weight reduction is a key factor in improving fuel efficiency and overall vehicle performance. Pure graphite is a lightweight material, which makes graphite rolls ideal for use in automotive parts that require strength without adding unnecessary weight. This characteristic helps manufacturers design more efficient, durable, and lightweight components, contributing to better fuel efficiency and performance.

7. Vibration Damping

The ability of pure graphite to dampen vibrations is another important reason it is used in the automotive industry. Components that experience vibrations—such as engine mounts and suspension parts—benefit from graphite’s natural vibration-damping properties. By reducing the impact of vibrations, graphite rolls help improve ride quality and reduce the stress on various automotive components.

8. Sustainability in Automotive Manufacturing

As the automotive industry shifts toward more sustainable practices, materials like pure graphite are becoming more important due to their longevity and recyclability. Graphite is a naturally occurring material and can be recycled multiple times without losing its core properties, making it an environmentally friendly option for the automotive sector. The long-lasting durability of pure graphite rolls also helps reduce the frequency of part replacements, contributing to overall sustainability.

Pure graphite rolls play a critical role in enhancing the performance, durability, and efficiency of automotive components. From providing high-temperature resistance and excellent lubrication to offering corrosion protection and vibration damping, graphite rolls are essential for automotive manufacturers striving to meet the demands of modern consumers. As the automotive industry continues to innovate and push the boundaries of technology, the use of pure graphite rolls will undoubtedly remain a key component in achieving success and meeting industry goals.

If you’re looking for high-quality pure graphite rolls for your automotive applications, contact us today for expert consultation and competitive pricing on custom-made solutions tailored to your needs!